JETSTAR HBW64UV

|

|

||||||||||||||||||||||||

FC-HBW64UV |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

Q'ty :

Enconomy grade /Hybrid printer

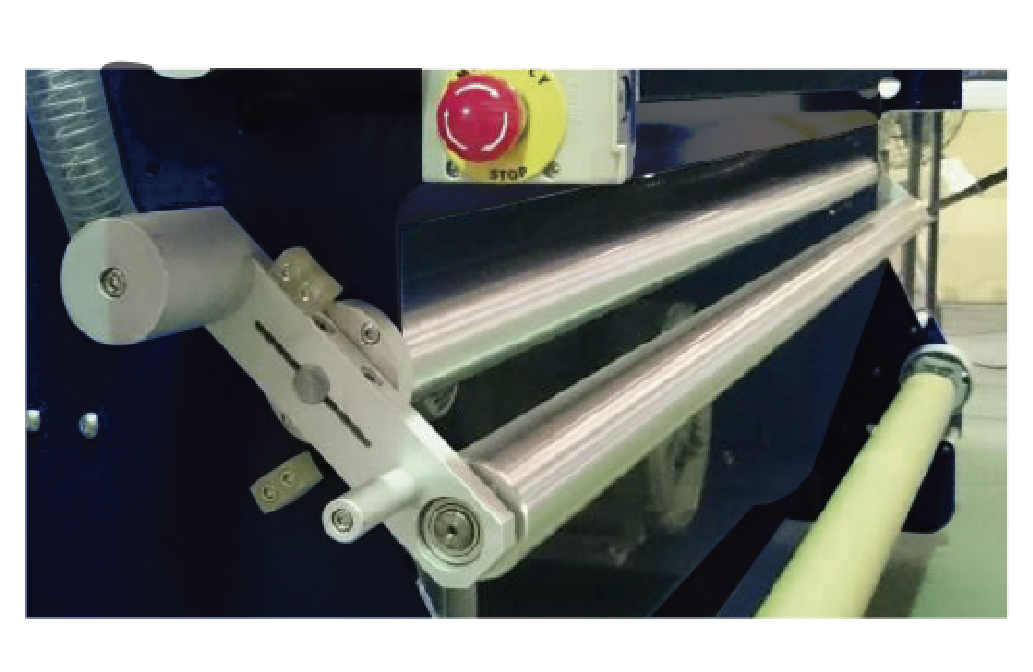

For roll to roll printer can load over 50Kg and up to 30cm diameter

of media.There are two air shaft to load and unload the medias quickly.

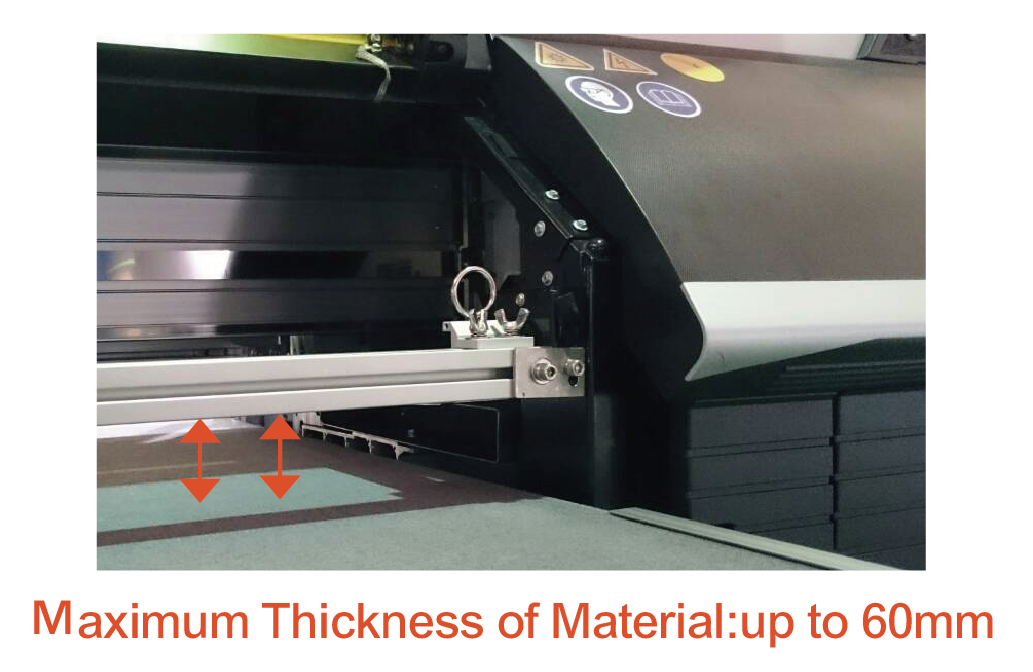

FC-HBW64UV can automatically detect the thickness of the material

with printing(up to 60mm),the

nozzle and the distance to maintain the

best material to achievethe best printing quality.

Can print various kinds of roll material,PVC,PP banner,

canvac,mesh,FLEX,Backlit media.

Accuracy and high quality printing with a wide range

of material ensures optimumprinting quality for various

types of media.is the highest cost efficiency machine.

Combination for head height adjustment ensures

optimumprinting quality for various types of media.

The blower allows the printer to take-up the media while printing even at the class fastest speed,and is turned on/off save power consumption when necessary.

Standard media rotary cutter runs in both direction makes your media cutting operation easier.Media clips on both sides hold the media ti prevent it from dropping on the floor and getting dirty after cutting.

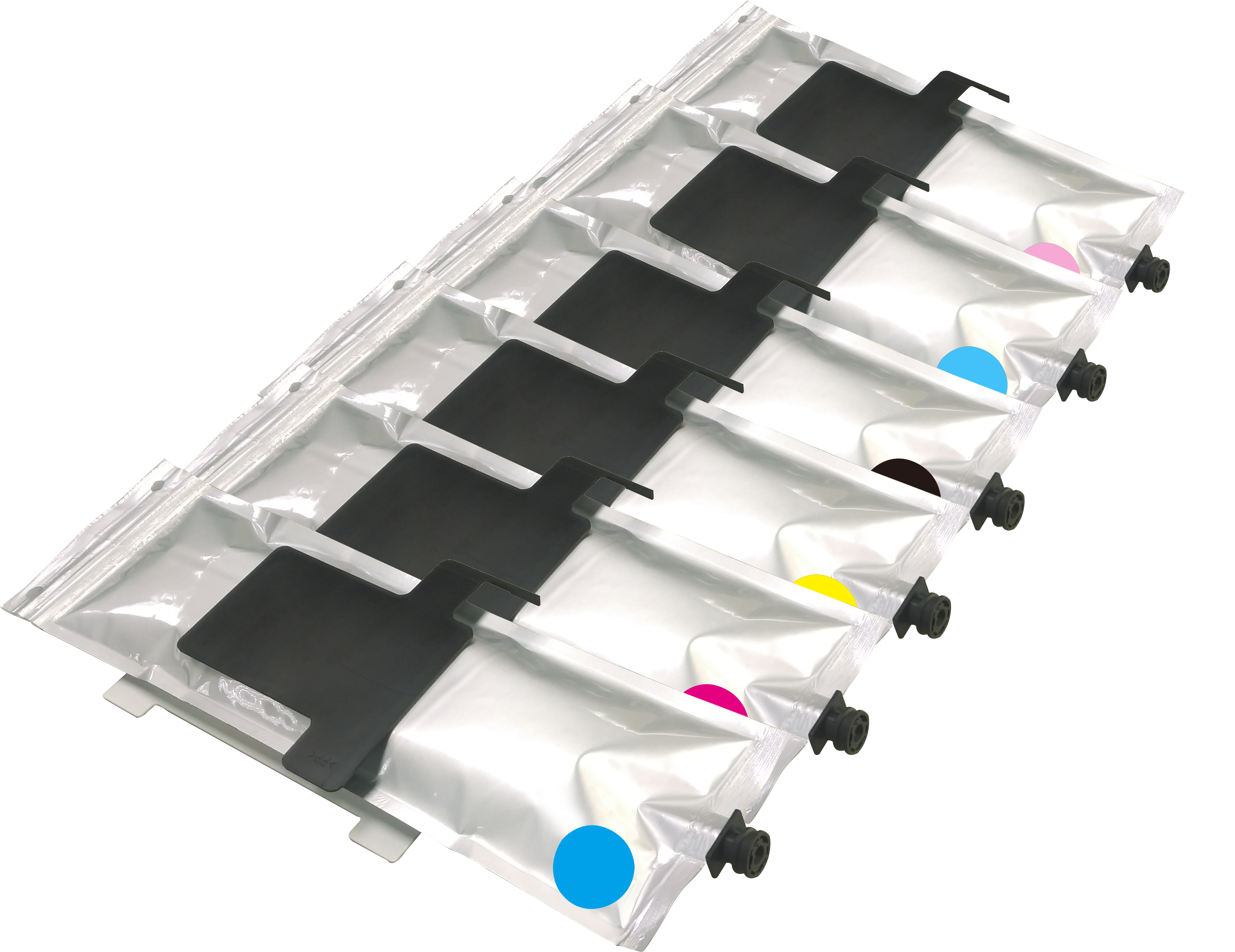

SJ UV Ink/ High quality

The newly developed SJ Inks offer a wide color

gamut , high vividness, high density,

excellent outdoor durability and low running costs in addition to the low level of oder.

Smart printing technology/ High Print Quailty

![]() Dynamically processing 3 different drop sizes to

maximize

Dynamically processing 3 different drop sizes to

maximize

image quality and maintain proper color density.

This innovative nozzle compensation function re-maps clogged

nozzles so you can continue to print with perfect image quality.

![]()

SmartPassTechnology 3 uses the most advanced algorithms and improved

mask patterns to reduce overspray and eliminate pass-to-pass banding.

![]()

CP Manager software allows you to monitor printer status, change print settings,

check ink levels, or see suggested maintenance on your PC.Operation and trouble

shooting guides are also available through CP_Manager.

![]()

Equipped with a function to give full play to the extreme

Inkjet Printer software.

![]()

|

SPECIFICATION |

|||

|

Model |

HBW64UV |

||

|

Print Heads |

SEIKO 256 |

||

|

Resolution |

900 dpi |

||

|

Maximum Print Width |

1616 mm |

||

|

Media Weight |

Roll |

50 kg |

|

|

Platform |

80 kg |

||

|

Paper Feed Method |

Roll/Sheet |

||

|

Maximum Thickness Of Material |

Roll |

Unlimited |

|

|

Platform |

up to 60 mm |

||

|

Ink |

Types |

SJ UV Ink |

|

|

Colors of Ink |

6 color (C/M/Y/K/Lc/Lm) |

||

|

Ink Capacity |

500 ml |

||

|

Media |

Vinyl/banner/backlit films/textiles... |

||

|

Take-up System |

Automatic tension take-up system |

||

|

Interface |

USB 2.0 |

||

|

Power Consumption |

Printer |

1350 W (in operation) |

|

|

Platform |

6000 W (in operation) |

||

|

LED UV Controller |

1100 W (in operation) |

||

|

Power Voltage |

Printer |

220V-60Hz |

|

|

Platform |

220V3ø |

||

|

LED UV Controller |

220V |

||

|

Operating Environment |

15-30℃,30to70% RH(with no condensation) |

||

|

Storage Environment |

5-35℃,10to80% RH(with no condensation) |

||

|

External Dimension |

2830(W)x1330(D)x1840(H) mm |

||

|

Weight |

535 kg |

||